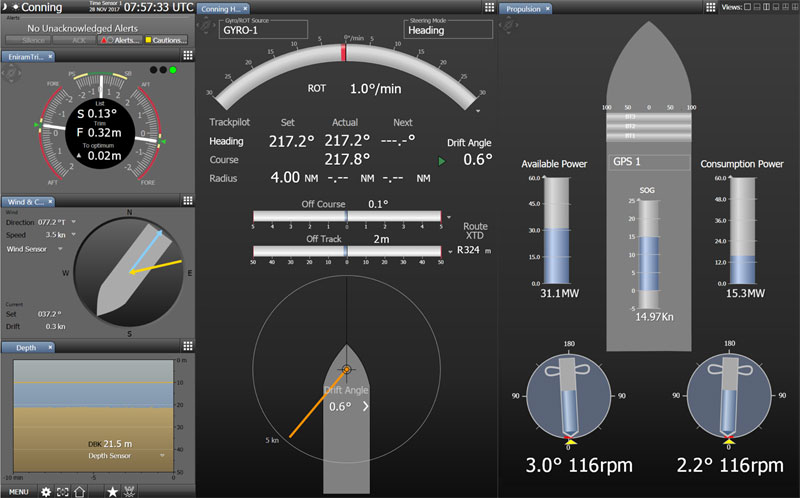

By introducing the Eniram Trim functionality, which allows immediate response to changing conditions and the maintaining of an optimum trim in real time, for use with Wärtsilä’s renowned Nacos Platinum control system for navigation, automation and dynamic positioning, substantial operator benefits can be accrued. These include better operational visibility, fewer workstations, and improved customer support in the collection and subsequent analysing of data. The combining of the Eniram and Nacos technologies makes the system easier to use, and creates greater availability of the needed guidance information. This information is available on all the Nacos screens, thus providing greater visibility and awareness. The overall result is improved efficiency and safer operation of the vessel.

“This programme fits well into Wärtsilä’s digitalisation strategy, our vision for a smart marine future and our roadmap of horizontal integration across Wärtsilä’s unrivalled product portfolio. We are uniquely positioned to utilise complementing technologies because of our extensive product portfolio and broad range of in-house competences, and this testing programme confirmed our ability to create a better value chain for data collection and analytics,” says Maik Stoevhase, Director Automation, Navigation, Communication, Wärtsilä Marine Solutions.

Eniram, a specialist company providing energy management technology to reduce fuel consumption and emissions, was acquired by Wärtsilä in 2016 to be a catalyst in creating a digital and performance driven company. The Eniram Trim analysis is based on a unique model of a vessel’s hydrodynamic characteristics, the information gathered by attitude sensors installed on the vessel’s hull, and the vessel’s automation and bridge systems. The input gained enables the Eniram Trim to calculate the optimal trim in real time, which leads to lower fuel consumption and greater cost savings than is possible with conventional trimming methods.

The Wärtsilä NACOS Platinum system represents a unique combination of control systems for navigation, automation and dynamic positioning, as well as power and propulsion. By integrating all these functions into a single system, the vessel can be navigated, controlled and monitored from various onboard positions. The truly multi-functional operator stations enable unequalled flexibility and convenience.